Members showed and discussed more woodturning aids and continued the discussion from the September 8, 2021 meeting.

Bill McDonald

This segmented wave bowl was cut with the circle jig. A sacrificial piece was used when cutting the project.

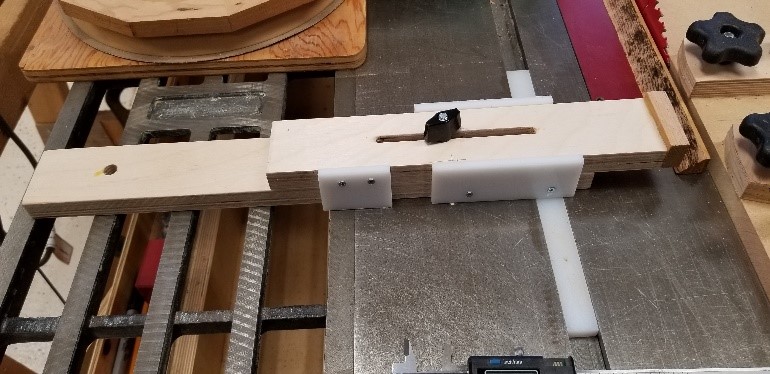

This example shows how a peppermill is held on the lathe. The two supports have been sized to fit the internal size of the opening. On the left is a piece of wood on the live center. On the right is UHMW, ultra-high molecular weight polyethylene. It’s yellowed from finish that has been used on previous projects. CA doesn’t stick to this material. UHMW is available in sheets or flat bar from Woodcraft, Rockler and Klingspor, but blocks that could be used in a chuck are available from www.interstateplastics.com.

Ed Jones

Dick Kelly

The ring that the lid sets on is turned while using the wooden jaws.

Gary Frank

Dan Hall

Ken Allen

Jay Loden

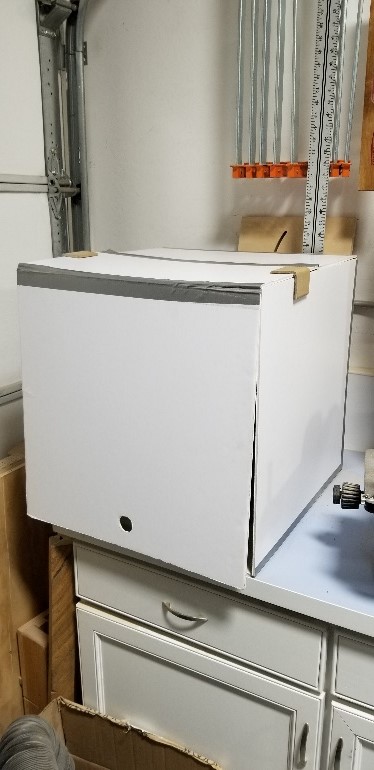

Since wall space was more available than counter space, Jay made this ‘super sophisticated’ sandpaper sorter. He buys sandpaper in bulk from Woodturners Wonders (https://woodturnerswonders.com/) and organizes them by size. He keeps a marker nearby to mark the backs if he’s using several grits during a project. The red grits are high grits with open weaves while the green grits work well with water or moisture and cut through finishes such as polyurethane. All have a Velcro backing.

Ray Schmelter

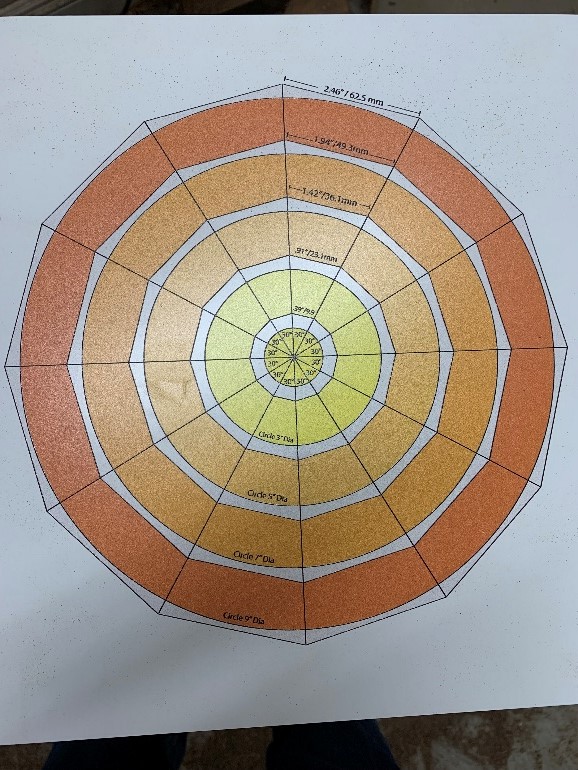

Some other sources of information on calculating segments for projects were suggested:

1. There is a free app for Android devices called Segment Calculator that gives the dimensions if you enter the inner radius, outer radius and the number of segments.

2. The Blocklayer website (https://www.blocklayer.com/woodturning-segmentseng.aspx) has a segment calculator with printable template. It is also free.

3. Segmented Project Planner is a software product created and sold by Bill Kandler. (http://www.segmentedturning.com/) It includes profiles, templates and cutting lists for projects. Although it was originally designed for a Windows platform, he gave information on using it with a Mac at this link: http://www.segmentedturning.com/XOM.htm.

The reference book, The Art of Segmented Woodturning by Malcolm Tibbetts, was recommended as a resource for learning how to put a floating base in a segmented vessel.

Ric Davis

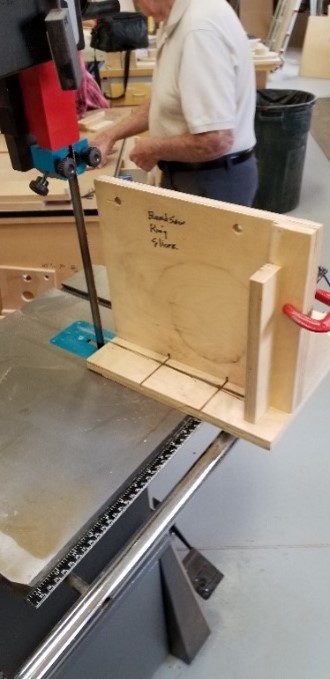

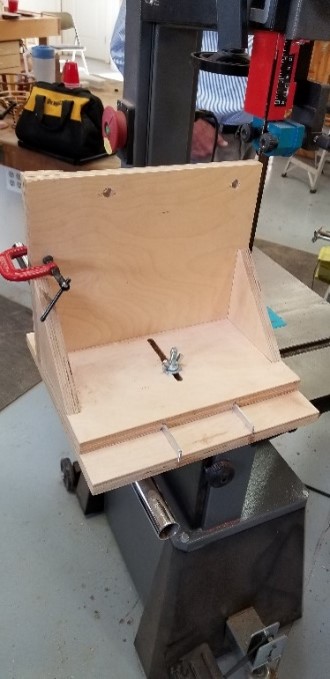

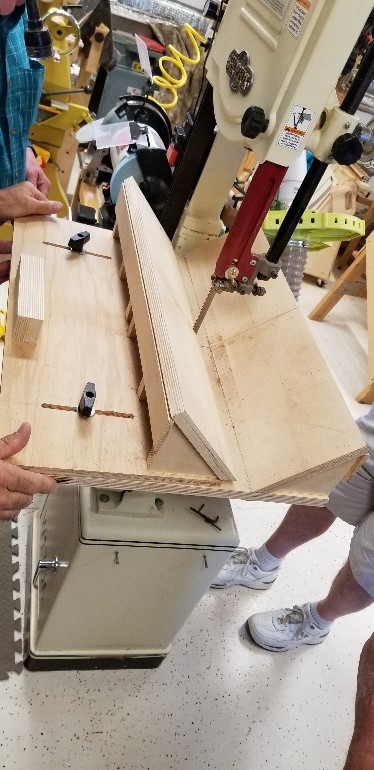

The discussions today and photos from members’ shops show similarities and individual adjustments to jigs made as aids for projects. Several members have circle jigs, for example, and comparing the photos and descriptions prompted ideas for improvements and changes depending on project needs. From simple to complex, those ideas are the value in sharing these discussions as part of Chips and Grits.